And to kick-start the transformation, the company allowed all staff to have a voice, “and more importantly an opportunity to tell their own story”.

“These discussions then move onto values and aspirations as we highlight all things that bind us together. We only get transformation when there is a strong emotional component.” It was also important to break the pattern of hierarchical control.

Service

Work started here as it was the most ‘factory-like’ part of the dealership and therefore had the most in common with TPS.

The work cycles are relatively short, meaning repetition and the work is visible on the shop floor. “It also helps that people in aftersales are often by nature more structured and disciplined in their approach to their work than many of their vehicle sales colleagues,” O’Donoghue said.

The customer value he aims for is uninterrupted mobility, delivering right first time quality, on time, every time, starting by separating the work into predictable and unpredictable, and then organise the predictable work in a flow that is moved on unit at a time.

Typically half the number of vehicles coming into the service centre falls into the predictable category.

Studying the work and the methods used to eliminate waste starts around the ramp with an analysis of movement and availability of tools and parts, by the second and by the metre.

Each variation was recorded – and videoed – and the workshop team watched at each step as a means of encouraging everyone to find the best process and witness the results.

“Putting two people on a vehicle and sequencing their work so they only do the necessary and value-adding tasks and have a standard way of doing every task has cut time taken dramatically.”

The measure the company use is taking the OEM allowed flat rate time for a job (the time you are allowed to charge for) and dividing by the actual time taken. It is typically getting efficiencies of 260%, in an area where 120% is considered very good.

“The service centre has proved to be our most valuable training ground for moving to a new way of thinking. It showed us the value of the team leader position, the importance of measuring at the bay and the benefit of quick response to problems identified by the front line workers.

“It also gave credence to the genuine involvement of staff and built their confidence as they contributed to counter measures.”

Examples include using head torches to free a technician’s hands and with people working under a lift, choose two the same height to ensure both are comfortable.

The project allowed the company to offer a new product, ‘fixed time service’.

For routine maintenance it can guarantee a turnaround time and work to a booked schedule of half hour fixed time slots. The standard work is completed in 23 minutes, leaving time to deal with small additional work that may be found such as replacing bulbs, wipers and brake pads. This gives a throughput of 16 jobs for each day – usually around 20 hours of paid work. The industry norm would be five jobs per day per lift and 10 hours of sold labour.

The next step was to expose the process to the customer, with the service parking space (the green bay) moved to what was showroom space right at the dealership entrance.

Keeping the customer on the premises in fixed time servicing eliminates communication time and on permissions for additional work.

“Even where we have not reached the fixed appointment stage, the increase in reliability and throughput has made dramatic contributions. On one site where they were faced with a sudden increase in demand, the DP credits the green bay performance as being the difference between demise and survival.”

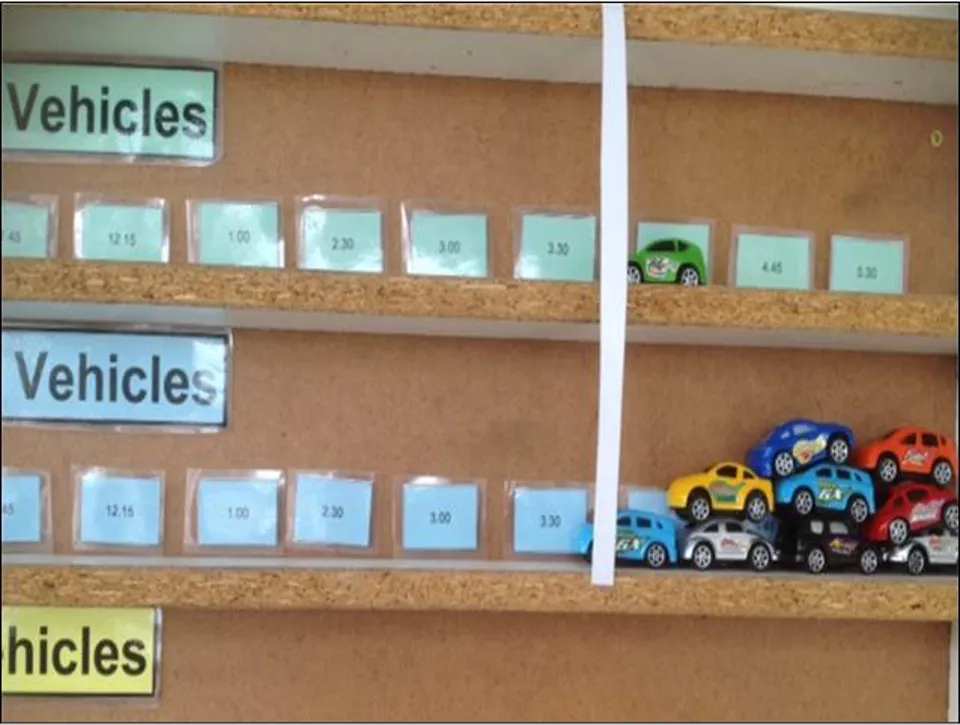

To make the flow work the company, O’Donoghue said, made the work, process, progress, problems and measures visible (see below).

“Once you do that, you can work to takt (average unit production time needed to meet customer demand) and resource to meet it. It you are predictable you can get synchronisation with other areas and speed up the flow even more. If you are unpredictable then I will buffer against your unreliability and the process goes into a vicious cycle of deteriorating performance.”

Pictures: demonstrating management of valet control, the final stage of Express Service, in a Halfway dealership

Pre-diagnoses

Pre-diagnoses

The increased proportion of work that can be made predictable means O’Donoghue’s company has been working on a pre-diagnoses process for more complex work. The process concentrates on identifying all work required, not completing it. The necessary authority to go ahead with the work and sourcing of parts then takes place while the vehicle is in a holding area between ramps.

The vehicle then only moves onto the ramp when another technician (usually with lower qualifications) can do all the work that has been authorised without interruption.

“It improves the visual control as stagnation on ramps becomes apparent and can be dealt with. The most experienced technicians do the most challenging diagnostic work and they feed a number of junior technicians and we keep the ‘hands on the cars’, as support people can synchronise their efforts to keep the technicians doing chargeable work.”

O’Donoghue said the results so far had been encouraging and the company has been able to add about 20% more work to the predictable stream. And even accounting for the pre-diagnosis and repair time he is seeing efficiencies of 170% with an even greater impact on gross profit and quality as the appropriate skills are used.

Some of the lessons learned

> The solution will depend on the situation, which determines the outcome. There are common principles and even a standard sequence and process but the detail of the design and implementation is always responsive of the situation.

> There can be no roll-out. You cannot perfect on one site and package it for implementation elsewhere. “The best you can hope for is that you learn, that others learn and you keep doing so and by having an example and exposing people to it you can inspire the enthusiasm to learn and prepare for the next intervention and experiments.”

> Standard work is fundamental. No standard, no gap. No gap, no problem. No problem, no improvement. If you haven’t got a problem, go and make one. All progress comes from solving problems.

> The role of the team leader is pivotal to protect standard work and to ensure work progress is maintained. More than anyone else they are the guardians of quality and the best positioned to encourage continuous improvement.

* Terry O’Donoghue is COO of Halfway Group based in South Africa. It operates to Toyota CI standards and only the accents differentiate the business from those in the UK. He used the Lean Enterprise Academy on a regular basis to coach and teach Lean Thinking. If you would like to know more about the Halfway Group and its Lean project, contact Dave Brunt, LEA chief executive on 01600 890 590 or dave@leanuk.org.

Login to comment

Comments

No comments have been made yet.