Renault is converting its Flins plant into a new ‘Re-Factory’, which will be used to refurbish used cars and convert ICE models to more carbon-neutral powertrains while also developing new sustainable technology.

The car maker says the new plant will be the first European factory dedicated to the “circular economy of mobility”.

This project, which is part of the Group's transformation strategy, is expected to deliver a negative CO2 balance by 2030.

Currently, the Flins facility is used to produce the Renault Zoe and Nissan Micra. These operations will be consolidated into another plant to make way for the new strategy.

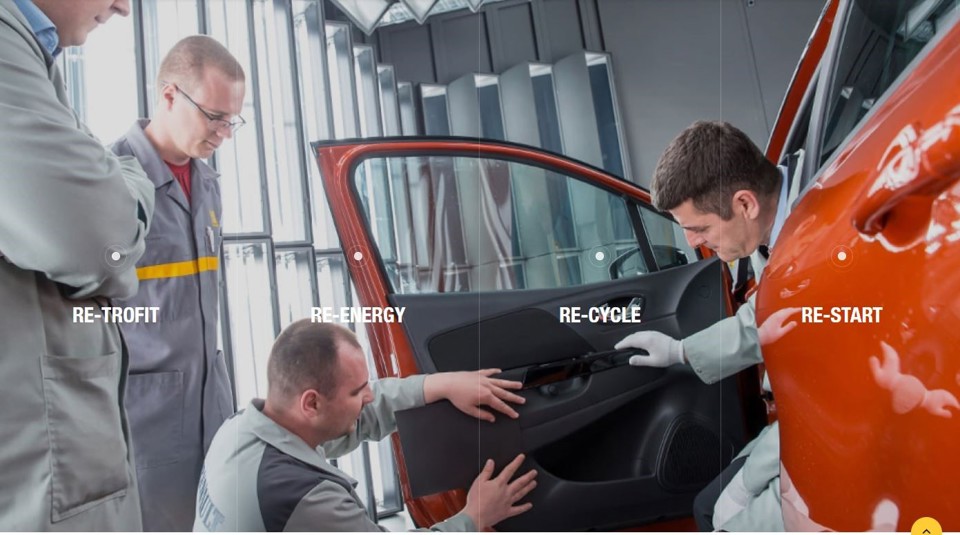

The Re-Factory will focus on four things:

- Re-trofit: this division will group together all the activities enabling the life of vehicles and their uses to be extended. Used vehicles will be reconditioned and ICE-powered cars and vans will be retrofitted with less carbon-based energy sources such as electric or hybrid engines. There will also be repair services for vehicle fleets and new mobility, and a service for manufacturing rare parts using 3D printers

- Re-energy: this cluster plans to develop the potential of applications arising from electric batteries and new energies to an industrial scale (including the optimisation of the first life of batteries, development of second life applications such as stationary energy storage, management of the end of life of batteries, and development of technical and supply solutions for new energies such as hydrogen).

- Re-cyle: this division will bring together all the Group's activities contributing to efficient management of resources and their flows to promote the supply of parts and materials in short loops and integrate a growing share of recycled or reused materials (installation of a line for dismantling end-of-life vehicles, extension of remanufacturing, reuse and recycling of materials).

- Re-start: to enhance and develop industrial know-how, but also to accelerate research and innovation in the circular economy, this cluster plans to house an incubator, as well as a university and training centre.

Jean-Dominique Senard, chairman of the Board of Directors of Renault, said: "This announcement is the result of the remarkable work of Renault's teams and constructive consultation with our stakeholders, including local authorities. The Re-factory is a new breath of life for Renault, its employees and for the entire region's dynamism. This project is based on our pioneering commitment to the circular economy, on our values, on our know-how and fully meets our ambition to positively transform our industry.”

Groupe Renault believes that the circular economy carries an extremely powerful growth potential and plans to recruit an additional 3,000 staff members at the new facility.

The car maker said it will reduce the turnaround time on remarking used cars from 21 days to six. The plant will also harvest parts from end-of-life vehicles including EV batteries.

"Re-factory will enable the Group to respond to the challenges facing mobility and automotive industry players today - and even more so tomorrow. This plant, with an objective of a negative CO2 balance by 2030, is fully in line with the Group's global strategy by combining circular economy, reduction of emissions, development of skills and the creation of new value-generating activities,” added Luca de Meo, CEO of Renault.

Login to comment

Comments

No comments have been made yet.