Workshop inefficiencies are losing car dealerships thousands, perhaps millions, of pounds every year.

Many times the vehicle comes in but isn’t ready to be worked on because the dealer doesn’t have the required details, manpower or parts. So, it either sits there taking up valuable workshop space, or has to be sent back and brought in again.

Another problem is a lack of trust from customers about the work that really needs to be carried out.

In addition, there can be a delay in a customer approving work, reducing ramp time efficiency, technician productivity and profit margins and increasing scheduling time. Plus there are additional costs such as providing a courtesy car.

So, what can dealers do to ensure the service process goes as smoothly and seamlessly as possible to ensure the best outcome for themselves and the customer?

The key, according to Lean Auto Retail coach John Kiff, is to make the work more predictable. That means pre-diagnosing the job before it arrives and using vehicle telemetry to find out key information so the work and parts needed can be better anticipated and planned for, resulting in more cars being fixed right first time and on time, he says.

“Dealers have been doing the same thing for years – the car pitches up at the workshop and everything the technician finds that needs doing is a big surprise,” says Kiff.

“By doing a simple pre-diagnosis before the car is brought in and a vehicle health check (VHC) when it arrives, you can ensure you have the right parts and more effectively allocate the right skills and time to do the job.”

Backing that up should be clear communication with the customer, said motor industry expert Mike Jones.

Backing that up should be clear communication with the customer, said motor industry expert Mike Jones.

That involves presenting all of the options available to the customer using easily understandable language, he says.

“Historically, there has always been a reticence to introduce this sales process into the service department,” says Jones. “But selling and doing the work is a team game and it’s absolutely essential in driving workshop efficiency.”

Building customer trust and rapport is also vital, argues Nathan Tomlinson, dealer principal of Devonshire Motors.

That requires helping customers make the correct decisions, he says.

“That’s so different to selling something,” says Tomlinson. “You also have to explain and agree necessary contact at or before drop-off, otherwise the slickest workshop and vehicle health check process in the world will be inefficient.”

“That’s so different to selling something,” says Tomlinson. “You also have to explain and agree necessary contact at or before drop-off, otherwise the slickest workshop and vehicle health check process in the world will be inefficient.”

Ensuring once the car is on site that staff can easily find it and get it onto a ramp also saves vital minutes for technician efficiency. One of Tomlinson’s tricks is pre-loading ramps each evening with the first jobs of the next morning, so once technicians clock on they’re straight into valuable work.

To achieve the best result, the dealer needs to ensure that, once a vehicle is in the workshop, any additional work is notified, agreed by the customer and completed effectively.

There are a range of methods at their disposal to accomplish this, including electronic VHCs and videos which can be used to show the work required and why, thus speeding up the approval process, increasing customer satisfaction and the likelihood of repeat business.

PERSONALISED VIDEO

One such solution is the CitNOW Workshop, which provides an efficient and transparent way of communicating with customers virtually, using personalised video.

The technology enables the technician to walk the customer around their vehicle while it’s up on the ramp and show them the work requiring completion, thus making them better informed and empowering them to approve the work quickly and simply.

“Technicians can ensure each vehicle spends considerably less time on the ramp while awaiting a response or approval from the customer, resulting in a much more efficient use of workshop time,” claims CitNOW Group’s chief revenue officer Alistair Horsburgh.

“Technicians can ensure each vehicle spends considerably less time on the ramp while awaiting a response or approval from the customer, resulting in a much more efficient use of workshop time,” claims CitNOW Group’s chief revenue officer Alistair Horsburgh.

“CitNOW Workshop also includes Notify, a service that delivers a notification to service technicians once the customer has viewed the video, prompting them to make a follow-up phone call at the optimum time.

“This instantaneous response increases the success rate of connecting with the customer, helps the workshop to make a stronger customer impact and, ultimately, improves the likelihood of work approval.”

It’s clear that customers respond well to video too. In a recent survey of car buyers, CitNOW found that 62% of respondents aged less than 50 said they are more likely to approve repair work if they were first sent a video that clearly shows what’s required.

What’s more, 65% of servicing work is approved by the customer within 30 minutes of receipt of a video from CitNOW Workshop and 26% within just 10 minutes.

Another solution is Keyloop’s Service Hub, which enables the customer to check-in on their mobile. It also provides personalised and comprehensive VHC reports.

Other platforms such as Tjekvik and Autopoint from eDynamix automatically message the consumer at key stages, and can even enable payment.

Regardless of the method, it’s paramount in the first instance to contact the customer via their preferred method, whether by phone, text, email or social media.

The rest of the process can be digitally connected and automated. Dependent on the platform, a video update on the service status and urgent work needed is sent, and once approval is given, it triggers automated digital documentation and online payment to be completed.

“Customers need to be communicated with on the platform that suits them, when it suits them, as it can delay the process if they aren’t responsive,” says Keyloop chief executive Tom Kilroy.

“Customers need to be communicated with on the platform that suits them, when it suits them, as it can delay the process if they aren’t responsive,” says Keyloop chief executive Tom Kilroy.

“To avoid this, dealers should maintain records of each customer’s preferred communication method and best times to contact them.

“Achieving a digitised servicing process requires that sophisticated digital solutions integrate all back-end and customer-facing processes seamlessly. As part of this digital solutions portfolio, dealer management systems should enable application programming interfaces (APIs) to permit third-party solutions integration, thereby offering an open platform for the dealer to have the freedom to choose his or her preferred service provider and tools.”

CUSTOMER AWARENESS

The process also needs to be joined-up so that all of the different technical components fit together, says Nick Squire, business unit development manager at Snap-On Business Solutions.

That means making sure each one is being used consistently and effectively so the customer is aware of what’s happening, he says.

“Once the car is in the workshop it’s key to have a clear and consistent VHC process in place,” says Squire. “It also requires using media such as photographs and videos effectively to show the customer exactly what they need to know, and thus get the job completed as quickly and efficiently as possible.”

Technology has certainly increased workshop efficiency, but without the right personnel, processes, training and leadership in place nothing would be achieved, says Coachworks Consulting managing director Karl Davis. Dealers also need to realise the opportunity to convert additional urgent work into sales in the first place, he says.

“That means understanding the difference between pre-calling a customer to make sure they are aware of the booking and carrying out the pre-conditioning work,” says Davis.

“It also requires having the right technical expert look at the booking in detail and determine what’s needed to get the job done.”

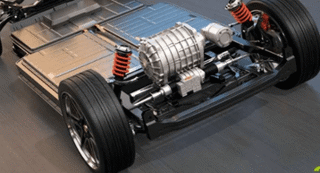

In the future, workshops will need to adapt to cater for electric vehicles. This presents a tremendous opportunity for dealers to better service the customer at the same time as improving their efficiency – something they should be working on already if they want to bolster their bottom line.

Author: Alex Wright

Login to comment

Comments

No comments have been made yet.