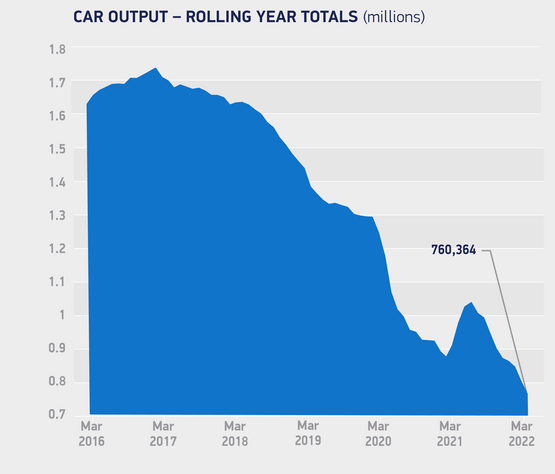

Urgent action is needed to protect the UK car manufacturing sector after production volumes slumped 32.4% on a COVID-impacted 2021, according to the Society of Motor Manufacturers and Traders (SMMT).

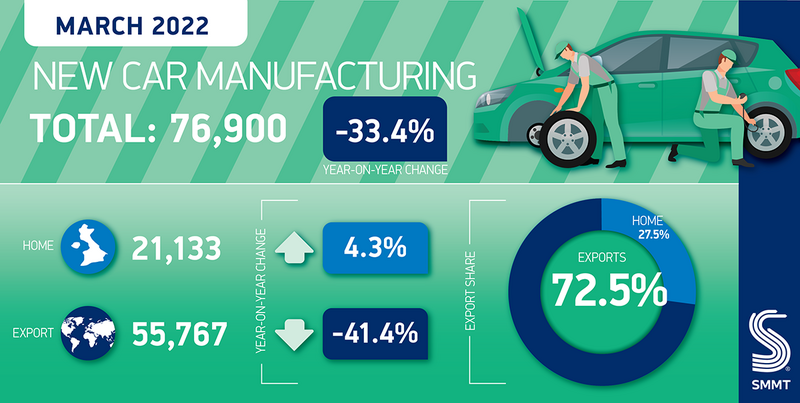

The sector’s March output delivered a 33.4% decline (to 76,900), its weakest performance since 2009 resulting in a Q1 production volume of 207,347 as the ongoing global shortage of semiconductors and other components dashed any hope of recovery.

Q1’s output was almost 100,000 units down on the 306,558 vehicles produced in a pandemic-affected Q1 2021.

Q1’s output was almost 100,000 units down on the 306,558 vehicles produced in a pandemic-affected Q1 2021.

SMMT chief executive Mike Hawes said: “Two years after the start of the pandemic, automotive production is still suffering badly, with nearly 100,000 units lost in the first quarter.

“Recovery has not yet begun and, with a backdrop of an increasingly difficult economic environment, including escalating energy costs, urgent action is needed to protect the competitiveness of UK manufacturing.

“We want the UK to be at the forefront of the transition to electrified vehicles, not just as a market but as a manufacturer so action is urgently needed if we are to safeguard jobs and livelihoods.”

AM recently reported on the impact of Russia's invasion of Ukraine on an automotive recovery from COVID-19 and its current supply issues.

Yesterday What Car? research suggested car buyers want to buy British to support the UK’s manufacturing sector.

The SMMT wants more practical help from Government, however.

It is calling for relief on energy costs equivalent to that afforded energy intensive industries and access to low cost and low carbon energy, comparable to European competitors, stating that these measures will “ensure the UK remains a competitive environment in which the latest and greenest vehicles can be ‘Made in Britain’”.

SMMT data showed that exports to the US saw the greatest decrease during March, dropping by -63.8% year-on-year, largely due to the closure of Honda’s Swindon plant in July 2021.

SMMT data showed that exports to the US saw the greatest decrease during March, dropping by -63.8% year-on-year, largely due to the closure of Honda’s Swindon plant in July 2021.

Seven-in-10 cars (72.5%) made in the UK were still exported, with the EU taking 67.0%, the US 8.2% and China 6.6%.

Production for the domestic market increased 4.3%, equivalent to 864 additional units.

Commenting on the SMMT’s Q1 production data, KPMG automotive partner Chris Knight said: “Car production volumes remain below pre-pandemic levels, but manufacturers have adapted, profiting from focus on a buoyant electric vehicle market, and prioritising components into higher-margin cars generally. Inflation driving up production costs further compounds this approach.”

Knight said that prioritising available components and materials into higher-margin vehicle production and sales had been to the detriment of some parts of the fleet industry.

He added: “With rental and leasing markets beginning to recover as travel and commuting again increases, leasing companies will be looking at which manufacturers have, and haven’t, supported them during these challenging times.

“An increase in hybrid working may of course change the nature of company car schemes forever and lead to less miles driven, but in turn it could drive more consumers, whether supplemented by a vehicle allowance or not, to look at rental options as an alternative to ownership.

“This was a trend we were already seeing pre-pandemic, particularly in urban areas and amongst younger consumers. And the tightening cost of living squeeze will only increase the number of people assessing whether short- or medium-term rental or leasing is a more affordable model for them than buying a vehicle.”

Login to comment

Comments

No comments have been made yet.